During the research phase for the writing of our company history “The Story of CalCedar: 100 Years of Pencil Supply History” one of the interesting documents unearthed in our company and family archives was a 1905 patent awarded to Philip Berolzheimer for a series of creative geometrical shaped pencil displays.

Tag Archive for: Incense-cedar

About a week back we passed through the half way point of our Centennial year here at California Cedar Products Company. We’ve been pretty quiet about all this on the Timberlines blog so far, but there has been lots of activity behind the scenes prepping a number of projects and events in celebration of achieving this milestone later this year on December 14th.

About a week back we passed through the half way point of our Centennial year here at California Cedar Products Company. We’ve been pretty quiet about all this on the Timberlines blog so far, but there has been lots of activity behind the scenes prepping a number of projects and events in celebration of achieving this milestone later this year on December 14th.

This all starts this week with a multi-day Centennial Celebration here in California which includes many of out top slat customers and pencil brands from the world attending to visit our facilities, participate in a sawmill and forestry tour and to join us in a final Gala dinner and show at the Hyatt Regency Lake Tahoe Thursday June 29th. Representatives from company’s such as Schwan Cosmetics, Schwan Stabilo, Mistubishi Pencil Co., Caran d’Ache, General Pencil Co., A.W. Faber-Castell, Musgrave Pencil Co., Cumberland Pencil (Derwent), Tombow and more will be in attendance in addition to a number of our wood suppliers and other special guests. The final dinner show event, “An Evening of Magic, Music and Memories” will be a fun event featuring some of our Blackwing musicians and some new faces. We are excited to have the chance to thank our customers, suppliers, employees and other collaborative partners for their long and positive relationships and support in reaching this milestone. In a sense we’re the youngster in this group as each of the companies I listed above have achieved the centennial mark and more, which is an interesting statement on the longevity of a number of the most famous companies and brands in the world’s pencil industry. We are proud to be associated with these industry partners and to be respected as a long term reliable supplier of Genuine Incense-cedar and other species pencil slats.

Our longtime friend and slat customer Masanobu Sakamoto at Sakamoto & Company, couldn’t attend, though sent us this decorated chocolate set shown a gift to help us celebrate our 100th year. Deco Choco is a new venture by Sakamoto branching out into customized chocolates, candies and snacks as an outgrowth of their decorated stationery, pens and pencils. They even have a bricks and mortar location in the Ginza area of Tokyo.

Our longtime friend and slat customer Masanobu Sakamoto at Sakamoto & Company, couldn’t attend, though sent us this decorated chocolate set shown a gift to help us celebrate our 100th year. Deco Choco is a new venture by Sakamoto branching out into customized chocolates, candies and snacks as an outgrowth of their decorated stationery, pens and pencils. They even have a bricks and mortar location in the Ginza area of Tokyo.

On the new product front our recent Blackwing Volume 73 release is a tribute to Lake Tahoe and was timed to coordinate with this event. Though not an official Centennial product it seemed a fitting choice and we’re happy to have teamed up with the League to Save Lake Tahoe to Keep Tahoe Blue, by donating $2 in the name of each Volumes subscriber. So if you’re not a subscriber already here’s an added chance to participate and help out with these by subscribing here.

A final project to give you a head up about is that I’ve been busy over the past year writing a history of the company “The Story of CalCedar: 100 Years of Pencil Supply History“. Just yesterday we received the first 100 copies in time to use as gifts for participants at this week’s Gala event, but the balance will be arriving soon and we may be making some available on Pencils.com for those interested once we get a handle. More to come on this project, and other centennial related items as we get through the busy but exciting week ahead.

This photo is of my father back in the 1970s during a visit to Kitaboshi Pencil Company in Tokyo, Japan, where I actually visited today. He is being presented a guitar produced using California Incense-cedar by a member of the Sugitani family who are customers using our pencil slats for their products. This gentleman is now retired, but I happened to see him today, he says he still plays guitar every day and had that guitar specially commissioned for my father as a gift. Look for my upcoming post about the history of Kitaboshi Pencil and their products that we will begin selling on Pencils.com next week. California Incense-cedar used in our pencil slats, our customers’ pencils using our slats (and in this one of a kind guitar) is fully compliant with the US Lacey Act which is the main subject of this post.

This photo is of my father back in the 1970s during a visit to Kitaboshi Pencil Company in Tokyo, Japan, where I actually visited today. He is being presented a guitar produced using California Incense-cedar by a member of the Sugitani family who are customers using our pencil slats for their products. This gentleman is now retired, but I happened to see him today, he says he still plays guitar every day and had that guitar specially commissioned for my father as a gift. Look for my upcoming post about the history of Kitaboshi Pencil and their products that we will begin selling on Pencils.com next week. California Incense-cedar used in our pencil slats, our customers’ pencils using our slats (and in this one of a kind guitar) is fully compliant with the US Lacey Act which is the main subject of this post.

The recent news of the US Fish & Wildlife Service raid and seizure of Rosewood and Ebony wood raw materials as well as guitars from Gibson Guitars and subsequent claims by Gibson’s CEO that the US government is over reaching in its actions has an interesting relevance to challenges also faced by our company and our customers in the U.S. pencil industry. Here are links to three articles about the Gibson issue over the past month:

- Trade Law Hits Note for Guitar Maker Gibson – September 19, 2011

- Gibson Guitars Wood Imports Case Raises Concerns – September 30, 2011

- Gibson Guitars CEO slams US raids as “Overreach” – October 12, 2011

At issue is the application of the 2008 Amendment to the Lacey Act, a law originally established in 1900 governing the illegal trafficking of hunted wildlife and game across state lines and since inception has continually expanded in scope and breadth to cover fish and plants. The law is administered by the Animal and Plant Health Inspection Service (APHIS) within the U.S. Department of Agriculture and jointly enforced with U.S. Department of Fish & Game which is the lead agency in the case against Gibson Guitars. Under the 2008 amendment the law was extended to plants, wood and products made from wood and plant materials. The amendment requires importers of applicable products to certify that the wood materials used in their products were not obtained from illegally harvested materials or include any protected or threatened tree species. The amendment implemented a number of documentation and declaration requirements that must now accompany each import shipment with respect to specific species used, country of origin of the trees from which the wood product was produced and statements relative to the legal harvesting of the trees used in the. Knowingly importing wood or wooden products covered by the law is a violation of the law subject to both civil and criminal penalties. Heralded as an improvement in environmental policy the amendment was also supported by the Bush Administration as a protectionist measure for the US timber and wood products industry against lower cost imported woods. While I have no specific knowledge of and cannot speak to the specific issues involved with Gibson’s case I can certainly state that illogical and inconsistent application of the rules process by government agencies responsible for enforcing the Lacey Act is a ripe example of the “law of unintended consequences” as with much government regulation. CalCedar has been deeply involved in addressing the 2008 Lacey Act amendment relative to compliance of our own pencil wood supply as well as understanding the impacts of the law on our company, our customers and the pencil industry supply chain as a whole. We have long taken an industry leadership position in assuring the wood resources we utilize are harvested from well managed forests according to applicable rules and regulations in any countries we source our wood from. We have and continue to support industry efforts to increase the overall sustainability and have been a pioneer in implementing FSC and SFI third party certification to an increasing proportion of our wood supply. Thus in concept implementation of the Lacey Act amendments in 2008 was a step in a positive direction with a goal of eliminating illegally sourced raw material or utilization of any threatened plant species. Though the standards applied as to what’s illegal or legal or threatened or not can vary from country to country as the Lacey Act simply requires compliance to the applicable laws in the country of harvest. Thus the level of added environmental protection here is inconsistent from country to country. The Lacey Act requirements added a whole new level of documentation and due diligence required for us to supply slats to our US based pencil manufacturing customers. This included updated investigations and documentation of our wood supply chain and added costs of consulting in the investigation with an accredited third party certification agency as to appropriate precautions including the added burden to segregate and/or eliminate any wood of potential concern and to maintain clear chain of custody of all our through the supply chain. All of this was already occurring with respect to our FSC and SFI material in both Cedar and Basswood, but we felt it important to apply these processes to the balance of our Basswood supply chain. Where we could not clearly document exact origin we sorted out the material to create yet another classification of inventory. Thus with respect to our Basswood pencil slats we now must keep separate inventory and track three different groups of products; FSC certified, Lacey Compliant and standard inventory which we do not believe is a compliance concern but will not take the risk of selling into the US market without clear chain of custody back to the forest. However, this burden of declaration documentation was not extended to the importers of pencils themselves. Thus wood sold to our customers who produce pencils in the US is subject to the documentation requirements while finished imported pencils are not, placing an added burden on U.S. pencil producers. Given that the majority of pencils consumed in the U.S. today and before the amendment took effect were imported this inconsistent application of the statute to intermediate vs. finished products hardly serves to protect US manufacturing jobs or to ensure that the majority of pencils sold in the US are indeed Lacey Act compliant. This does not mean many or even most pencils are not compliant, just that the chances are higher that they could be. As far as musical instruments are concerned importation of pianos and stringed musical instruments, including guitars, seem to have become subject to the documentation and declaration requirements in April 2010, so in this case it appears the compliance playing field may be a bit more level between US and Foreign producers in that industry. Next, the rules are not very specific on the level of sufficient due diligence to protect an importer from prosecution and civil and criminal penalties under the act. The “due care” principal is used which is generally contextually applied depending upon the level of organizational expertise and level of involvement in the supply chain of the importer of record. Thus as an experienced wood products manufacturer standards for “due care” applied to our company may be interpreted by the relevant agency differently than that of an importer of finished pencils who tends to rely solely upon the level of documentation they choose to request from their supplier. In many cases such suppliers are simply foreign trading companies, not manufacturers themselves, relying on the say so of their own supplier. With much pressure put on the price of imported pencils and other wood products this provides some level of incentive to less ethical suppliers to fudge in the information provided to their U.S. import customer. If a U.S. importer does not perform an on the ground investigation or use a knowledgeable third party certification agency, which is not specifically required under the statute, and simply relies on the paperwork provided by their supplier, they may be at some elevated risk of exposure to prosecution as to whether they employed “due care” in the event there is ultimately some problem found with the legality of the raw materials. This essentially becomes a risk management exercise for each importer with differing levels of risk tolerance and exposure. Finally, as a knowledgeable U.S. company operating our own facility in China and selling globally we are more at risk of punishment under this U.S. act than are our foreign competitors. It’s going to be difficult for a U.S. importer penalized under the act to recoup any fines even if they have some form of guarantee. As such we’ve taken a more conservative approach to managing this issue in our company. This is also more costly than most of our foreign competitors especially those who are exporting finished pencils to the US where no specific requirements for their U.S. import customers to file the import declarations. This does not mean those pencils are not subject to requirement to be legally harvested, but they have less risk of being challenged as to compliance.

As a company we are continually working to insure that an increasing portion of our wood supply to the pencil industry actually is part of one or more accepted third party certification programs, most specifically FSC or SFI, under the PEFC umbrella. Given both inflationary cost and supply developments with respect to Basswood in China resulting from the Chinese government now enforcing greater harvest restrictions we are currently testing and introducing a new 100% FSC certified product line named Pacific Albus. This new product is U.S. plantation grown and fully Lacey Act compliant. We see Pacific Albus becoming increasingly important versus Chinese or Russian grown Basswood in our company’s supply program and is a product that will be proprietary to our company. I expect to post more about this new product range as we move forward with greater adoption and acceptance into the industry by our customers.

My wife and I recently completed a driving vacation down the California coast which included an overnight stop in San Simeon where we visited Hearst Castle. Each of us had been there separately as children, but clearly our appreciation of this architectural gem and the vision of William Randolph Hearst is much greater with a bit of seasoning over the years. Having designed, built and remodeled a couple very modest houses ourselves, we found it amazing to see what Hearst and his Architect Julia Morgan accomplished over 28 years that they collaborated on this property. There is a very well done movie in the visitor center which covers Hearst’s life and the influences that lead to his personal attachment to and vision for this estate as well as his close working relationship over several decades with Julia Morgan. Full of quite a few old home movies, it’s just a great chance to learn about their creative working process in addition to the history of the property. This often involved tearing down and rebuilding many aspects of the project as well as designing to complement and feature the amazing, historical pieces of art, furniture and architectural treatments imported from throughout Europe.

My wife and I recently completed a driving vacation down the California coast which included an overnight stop in San Simeon where we visited Hearst Castle. Each of us had been there separately as children, but clearly our appreciation of this architectural gem and the vision of William Randolph Hearst is much greater with a bit of seasoning over the years. Having designed, built and remodeled a couple very modest houses ourselves, we found it amazing to see what Hearst and his Architect Julia Morgan accomplished over 28 years that they collaborated on this property. There is a very well done movie in the visitor center which covers Hearst’s life and the influences that lead to his personal attachment to and vision for this estate as well as his close working relationship over several decades with Julia Morgan. Full of quite a few old home movies, it’s just a great chance to learn about their creative working process in addition to the history of the property. This often involved tearing down and rebuilding many aspects of the project as well as designing to complement and feature the amazing, historical pieces of art, furniture and architectural treatments imported from throughout Europe.

During our overnight we lodged at The Morgan at San Simeon, decorated throughout with an amazing collection of her original architectural design renderings for many aspects of the Castle. Almost all of these were done in graphite and colored pencil. This collection represents a remarkable exhibition of art and has strengthened my own interest in historical architecture and the use of pencil as a creative medium in this trade. I’ve shared a few of my photos of the Morgan drawings here. Amazing details down to the designs of the stair risers all around the property, and untold design features throughout. The bottom of each print includes a description of the item and the inscription “Mr. W. R. Hearst San Simeon, Julia Morgan, Architect” along with the date of the drawing, all in pencil. The one photo of the property I included below demonstrates how the tile risers become an integrative component of the overall architectural design.

During our overnight we lodged at The Morgan at San Simeon, decorated throughout with an amazing collection of her original architectural design renderings for many aspects of the Castle. Almost all of these were done in graphite and colored pencil. This collection represents a remarkable exhibition of art and has strengthened my own interest in historical architecture and the use of pencil as a creative medium in this trade. I’ve shared a few of my photos of the Morgan drawings here. Amazing details down to the designs of the stair risers all around the property, and untold design features throughout. The bottom of each print includes a description of the item and the inscription “Mr. W. R. Hearst San Simeon, Julia Morgan, Architect” along with the date of the drawing, all in pencil. The one photo of the property I included below demonstrates how the tile risers become an integrative component of the overall architectural design.

Julia Morgan’s story is a fascinating tale of one of America’s first leading female architects. Graduating in 1894 as Civil Engineering student from University of California, Berkley  she was the first woman to be accepted and graduate with a degree in architecture from the Ecole des Beaux-Arts in Paris. Returning to San Francisco and employed by John Galen Howard, who was responsible for the UC Berkeley Campus Master Plan at the time, she worked on designs of several buildings. This included two endowed by Phoebe Apperson Hearst, William Randolph’s mother. This initiated a long relationship between Morgan and the Hearst’s that spanned over 30 years and included multiple projects on both Hearst Estates as well as several newspaper buildings. Beyond her most famous work on Hearst Castle, Morgan was one of several architects contributing to the Bavarian village themed Wyntoon estate on the Hearst’s 67,000 acre forest property along the McCloud River just south of Mt. Shasta. Outside the broad Patronage of the Hearst family, Morgan did extensive work designing buildings for YWCA (including the Asilomar Conference Center) and several other women’s educational institutions such as Mills College. In all something like 700 buildings in California are attributed to her body of work and much has been done by historians documenting her contribution to the field of architecture.

she was the first woman to be accepted and graduate with a degree in architecture from the Ecole des Beaux-Arts in Paris. Returning to San Francisco and employed by John Galen Howard, who was responsible for the UC Berkeley Campus Master Plan at the time, she worked on designs of several buildings. This included two endowed by Phoebe Apperson Hearst, William Randolph’s mother. This initiated a long relationship between Morgan and the Hearst’s that spanned over 30 years and included multiple projects on both Hearst Estates as well as several newspaper buildings. Beyond her most famous work on Hearst Castle, Morgan was one of several architects contributing to the Bavarian village themed Wyntoon estate on the Hearst’s 67,000 acre forest property along the McCloud River just south of Mt. Shasta. Outside the broad Patronage of the Hearst family, Morgan did extensive work designing buildings for YWCA (including the Asilomar Conference Center) and several other women’s educational institutions such as Mills College. In all something like 700 buildings in California are attributed to her body of work and much has been done by historians documenting her contribution to the field of architecture.

One final interesting connection between pencils and this story is that the Hearst’s McCloud River area timberland holdings include stands of California Incense-cedar which have historically been harvested and sold by the Hearst Corporation for use in pencil manufacturing. From 1979 to 2003 our company owned and operated a saw mill at McCloud, CA, which was originally established as the McCloud River Lumber Company in 1896. Even before that we were producing pencil stock lumber in our Mt. Shasta City mill from the early 1960s until the early 1990s. The nearby Hearst lands historically provided some portion of the cedar used by both saw mills to produce pencil stock that was then sent on to our slat operations in Stockton to make pencil slats sold to our pencil manufacturing customers. Even though our manufacturing supply chain is designed much differently today, producing slats in China, we still receive some pencil stock we are purchase from other suppliers who buy cedar logs from the Hearst lands. Thus the Hearst property has been participating in some small portion of the pencil industry’s sustainable cedar supply for 50 years or so.

One final interesting connection between pencils and this story is that the Hearst’s McCloud River area timberland holdings include stands of California Incense-cedar which have historically been harvested and sold by the Hearst Corporation for use in pencil manufacturing. From 1979 to 2003 our company owned and operated a saw mill at McCloud, CA, which was originally established as the McCloud River Lumber Company in 1896. Even before that we were producing pencil stock lumber in our Mt. Shasta City mill from the early 1960s until the early 1990s. The nearby Hearst lands historically provided some portion of the cedar used by both saw mills to produce pencil stock that was then sent on to our slat operations in Stockton to make pencil slats sold to our pencil manufacturing customers. Even though our manufacturing supply chain is designed much differently today, producing slats in China, we still receive some pencil stock we are purchase from other suppliers who buy cedar logs from the Hearst lands. Thus the Hearst property has been participating in some small portion of the pencil industry’s sustainable cedar supply for 50 years or so.

A nice clear, cool day in the Collins Almanor Forest today where I visited Collins Lumber Company in Chester, CA. Collins is our supply partner for the FSC Certified Incense-cedar lumber used in our own ForestChoice Pencils and CalCedar’s FSC Certified pencil slats supplied to manufacturer such as Caran d’Ache.

A nice clear, cool day in the Collins Almanor Forest today where I visited Collins Lumber Company in Chester, CA. Collins is our supply partner for the FSC Certified Incense-cedar lumber used in our own ForestChoice Pencils and CalCedar’s FSC Certified pencil slats supplied to manufacturer such as Caran d’Ache.

It was nice to be back in a more rural forest setting even if just for the day including stopping in town for a Latte at The Coffee Station. Chester at this time of year has a great feel of small town America, not so busy as during the Summer months with all the vacationers to Lake Almanor and the Lassen National Park. Checking the local paper over coffee the big news of the day was a classic example of a small town scandal. The front page story discusses the community healing process initiated to come to terms with the decision of the local high school principal to dispose of 25-30 sports trophies. In one of my favorite comments one Alumni stated that disposing of the trophies showed a “total lack of understanding about small schools and small towns.”

Following our productive meeting with Collins Pine we drove to Redding to meet with another supplier Sierra Pacific Industries which provides our cedar lumber under the Sustainable Forest Initiative (SFI) & PEFC certification programs. Our drive took us through the Collins Almanor Forest, Lassen National Forest, Lassen Volcanic National Park and timberlands owned by Sierra Pacific. The two forest images here are of the Collins including a small group of Incense-cedar trees about 50 years old plus the Coffee Station.

Following our productive meeting with Collins Pine we drove to Redding to meet with another supplier Sierra Pacific Industries which provides our cedar lumber under the Sustainable Forest Initiative (SFI) & PEFC certification programs. Our drive took us through the Collins Almanor Forest, Lassen National Forest, Lassen Volcanic National Park and timberlands owned by Sierra Pacific. The two forest images here are of the Collins including a small group of Incense-cedar trees about 50 years old plus the Coffee Station.

In an upcoming post I’ll be covering some more detailed updates and views on issues related to the FSC and SFI/PEFC certification schemes as well as information related to the developing carbon offset credit market with respect to California forests.

In an upcoming post I’ll be covering some more detailed updates and views on issues related to the FSC and SFI/PEFC certification schemes as well as information related to the developing carbon offset credit market with respect to California forests.

In prior posts I’ve focused on many developments affecting the Pencil industry and how companies have reacted in their business operations and strategies to these external influences. I’ve covered trends such as globalization and growth of imports; consolidation within both manufacturing and distribution channels and the resulting rationalization of brand ranges and manufacturing facilities. I’ve also commented on anti-dumping duties and other trade, environmental and product safety issues. Most of these posts have focused on larger industry players and their adaptation and leadership embracing change to remake their companies (i.e. generally the acquirers and market share leaders) with both positive and negative impacts on quality, customer perceptions, market share, and other typical measures of business and industry success.

In prior posts I’ve focused on many developments affecting the Pencil industry and how companies have reacted in their business operations and strategies to these external influences. I’ve covered trends such as globalization and growth of imports; consolidation within both manufacturing and distribution channels and the resulting rationalization of brand ranges and manufacturing facilities. I’ve also commented on anti-dumping duties and other trade, environmental and product safety issues. Most of these posts have focused on larger industry players and their adaptation and leadership embracing change to remake their companies (i.e. generally the acquirers and market share leaders) with both positive and negative impacts on quality, customer perceptions, market share, and other typical measures of business and industry success.

Proudly made in the USA is a vital principle for General’s® brand pencils. General refuses to import cores and leads or increasing proportions of raw, semi-finished or even finished pencils as opposed to all other US based pencil manufacturers who have long since adopted such practices.

Proudly made in the USA is a vital principle for General’s® brand pencils. General refuses to import cores and leads or increasing proportions of raw, semi-finished or even finished pencils as opposed to all other US based pencil manufacturers who have long since adopted such practices.It’s been awhile since I’ve posted much related to forestry and the timebr business here. Last night this segment appeared on NBC Nightly News. It features the sustainable forestry efforts of Collins Pine Company which has had a long relationship with our company. Collins is a an important supplier of FSC Certified Incense-cedar used in our ForestChoice pencils and our FSC certified slats sold to other pencil companies around the world.

I do find Brian William’s intro statments like “You can’t see the forest, because they’re gone!” coupled with the use of images of recent clearcuts rather misleading relative to the actual reality of responsible forestry practice in the Pacific Northwest. Collins is clearly a leader in committing all their timber operations to FSC certification process and in the manner in which they run their operations. I applaud them and am happy to be collaborating with them in bringing sustainable wood products to market. However, they are just one example of numerous companies with good sustainable forestry practices.

Yesterday I came accross the following post “¿Cómo se meten las minas en los lápices de madera?” which answers just this question on the general interest Spanish language blog Ya está el listo que todo lo sabe (Here is the list of everything to know). The post includes a brief history of the development of the graphite pencil and a description of the pencil manufacturing process. This post as many other websites I have found over the years has liberally borrowed the photo from our How to Make A Pencil page on our Incense Cedar Institute Pencil Pages site on how pencils are made.

What I found most interesting about this post was the “commentarios” left by readers and in particular a long treatise on the wood used in pencils by Dr. Amio Cajander who provided a knowledgeable discussion of the use of Incense-cedar ,other pencil woods and even composite substitutes in his long comment in addition to describing some of the technical factors that make for a good pencil wood. He even generously noted my Timberlines blog as a resource for his information for those who wished to practice thier English. Additional comments indicated readers seemed generally interested in learning about how the pencil was made. This is not unlike my experience with reactions to my Timberlines posts and our feedback over many years from information provided on the Incense Cedar Institute Pencil Pages.

While my Spanish is just okay, I was able to make my way through this post relatively easily and it was good practice. So for those interested in testing their Spanish, practicar aqui.

Honestly, it’s nice to see that there is such interest in the manufacturing process and the pencil itself from all over. I would take the time to link to a few other foreign language sites on the topic of how pencils are made that I’ve found over the years, but unfortunately I never bothered to save any of those links. So if you’re visiting from another country and know of any such web pages in your native tongue please feel free to link to these in a comment to this post.

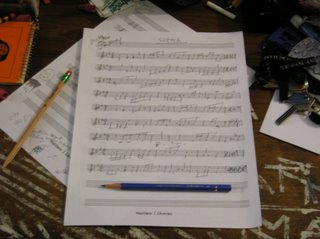

I received the attached photo and note from Matt Downey demonstrating how he’s using our Palomino pencils for his musical efforts.

I received the attached photo and note from Matt Downey demonstrating how he’s using our Palomino pencils for his musical efforts.

“Hey here is what is called a sketch, rough musical ideas on paper that will eventualy find their way into a peice. In this case the second movement of a string quartet. I love sketching with this Palomino pencil. The line is good and dark and the lead is nice and smooth. The wood has that smell (you know the one I mean) and it is all so conductive to the creative impulse in me. Sketching could be called material generation for the purpose of composing but I like to think of it as composing anyway even though it is so incomplete.-Matt

PS – I think you can spy a Mongol chilling in the backround. play an I SPY game with it.”

Yeah, I see it there in the corner and am glad to spot a ForestChoice pencil as well. Thanks for sharing and keep on creating.

We have several long awaited new arrivals this week to expand our range of KUM sharpeners at Pencil World Creativity Store.

We have several long awaited new arrivals this week to expand our range of KUM sharpeners at Pencil World Creativity Store.

First, is our special edition Palomino Long Point Sharpener. This is a premium “Automatic” long point sharpener from KUM that features a two step process to acheiving a perfect point. The first step sharpens just the wood leaving the graphite core mostly untouched for step two; sharpening the graphite core to a fine even point. Prior to being exposed to this two step sharpener I was personally a devotee of the KUM metal wedge sharpeners, which I still enjoy for their simplicity, and clean short points when I’m using a Golden Bear or Prospector. However now I won’t touch my Palominos with anything but the Long Point sharpener. This provides a fine, crisp point that lasts longer between sharpening than the wedge point. When I was first introduced to this sharpener back at the Paperworld fair in Frankfurt by KUM owner-President Fritz Luettgens I knew I had to pair this one up with our Palomino pencils. The group at KUM was great to work with creating a series of color variations until we got just what we wanted, a nice translucent orange with our gold California Republic Palomino imprint on one side. Each sharpener comes with two spare blades and a cardboard case with operating instructions on the two step sharpening process.

Three other new KUM sharpener listings have also been added. The Softie Grip Magnesium II takes the one hole Magnesium sharpener and adds the ergonimic cushioning of a spongy grip to two sides. This feature provides a unique comfortable feel during sharpening. For another new container sharpener we’ve added the “Oval-Office-Large SOFTIE®-LINES” in blue and orange. This larger container sharpening includes the Magnesium two hole sharpener which can be removed for replacement. The softie lines feature provides a non-slip grip for handling the sharpener, but not the same cushioning effect of the Softie Grip. Next is a unique new combination product ensemble from KUM, the Groovy Blister Card Set. The Groovy set comes in three fun design styles and each set includes a decorates large Oval Office style sharpener with an eraser, 17cm ruler (sorry only metric measurement was available) and a unique graphite pencil produced from wood which has been stained black throughout. These sets will make great party favors or simply a nice gifts particuylary for girls in the 7 to 12 year old age group.

In celebration of the Germany 2006 World Cup we’ve also added a limited time Soccer Mania Promotion. Buy 5 10-packs of Spangle Soccer pencils and recieve a free KUM soccer sharpener. We have a limited group of seven soccer sharpeners and one of these features the Germany 2006 design so it’s first come first serve as to which sharpener you will receive. If you wish you can substitute any of our other Spangle 10 pack decorated pencil items if you don’t want all soccer pencils, just be sure to buy at least 5 packs total in one purchase and we’ll send the sharpener along.

Comming Soon: Two new listings for Golden Bear and Prospector triangular pencils.